06/06/2025

New Standards in Quality and Efficiency End-of-Line Inspection in the Automotive Industry

The automotive industry is at the heart of continuous change and innovation. In this dynamic sector, product quality and manufacturing efficiency are fundamental factors that determine companies' competitiveness. In this context, end-of-line inspection processes stand out as a critical stage that finalizes production lines. In this article, we examine in detail the effects of these processes on production quality. We also discuss the importance of end-of-line inspection in the automotive sector, the modern technologies applied, the role of automation, and best practices for successful inspection.

The Importance of End-of-Line Inspection in the Automotive Industry

End-of-line (EOL) inspection in the automotive industry is the final stage of quality assurance in the production process. Before vehicles are delivered to customers, they must pass through this critical checkpoint. Detecting errors early protects both customer satisfaction and brand reputation.

Through production line audits and quality tests, vehicles enter the market in flawless condition. These inspections minimize mechanical or aesthetic issues, boost production efficiency, and prevent unnecessary costs.

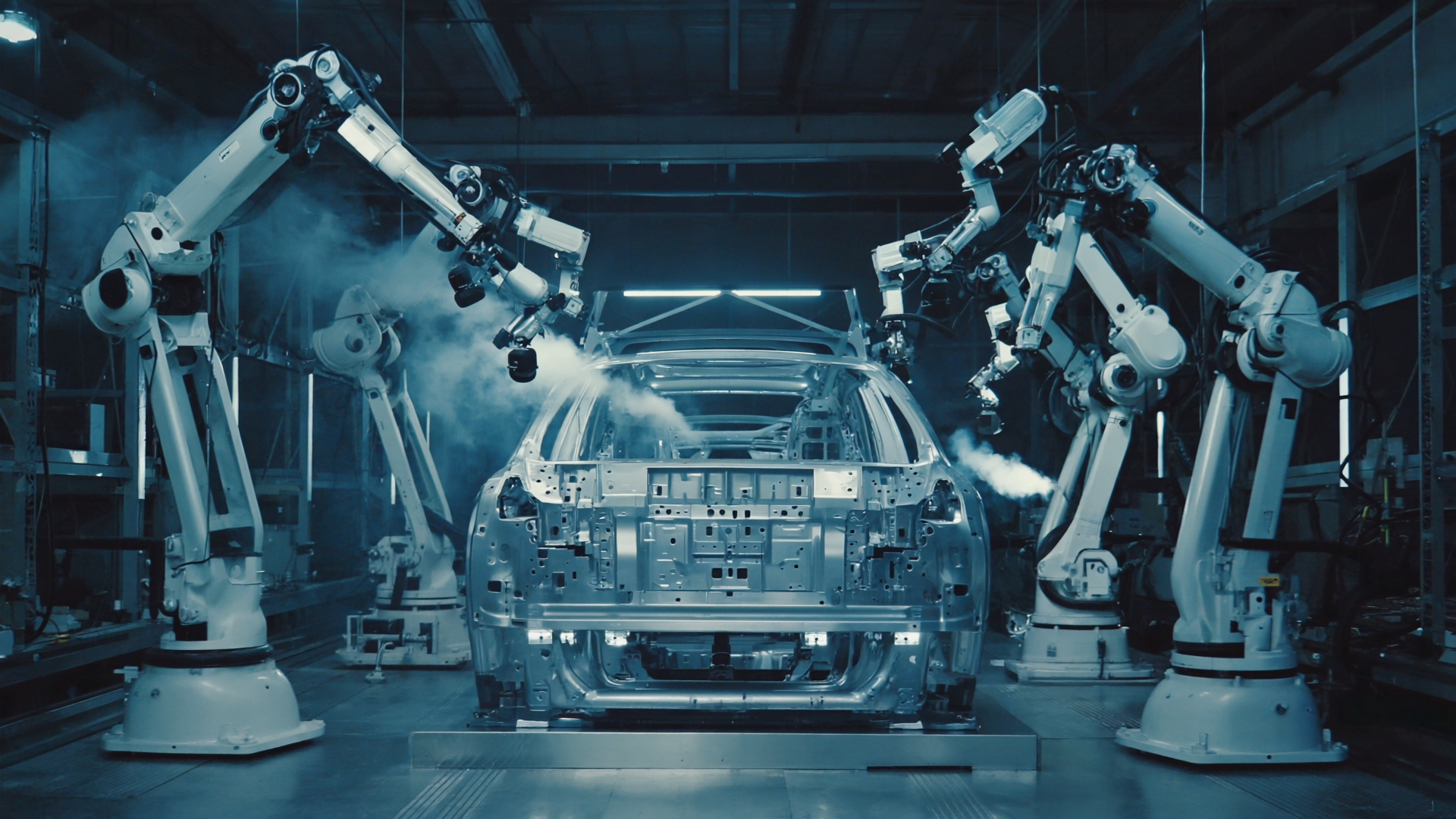

With the advent of new technologies, artificial intelligence and industrial image processing systems are now involved. These systems detect even micro-defects that the human eye might miss—taking quality to the highest level.

Overall, these processes aren’t just a requirement for automotive manufacturers—they’re a significant competitive advantage. End-of-line inspection acts as the final gatekeeper of quality.

How Does End-of-Line Inspection Affect Quality?

This inspection process confirms that every component in the vehicle functions correctly. It ensures the vehicle meets all quality standards before reaching the market.

Visual quality control in particular helps detect surface defects and assembly issues, ensuring that the product is in perfect condition. Industrial image processing can analyze details far beyond human capability.

AI technologies make these processes both faster and more accurate. Each component is visually analyzed, and defects are identified immediately. This accelerates production and reduces error rates.

Thanks to production line audits and automatic defect detection, quality increases, processes become shorter, and costs are reduced. These inspections contribute directly to both quality and efficiency.

The Role of Modern Technologies and Automation

Automation allows inspection processes to be completed faster and with fewer errors. Defective parts are caught early in the production line.

AI enables customized inspections for each vehicle. These machine-learning-powered systems enhance both production efficiency and product quality.

Industrial image processing systems detect defects within seconds. Automatic defect detection reduces human error and improves accuracy.

Best Practices and Tips for Successful Inspection

Automatic Defect Detection Systems: Catch faulty parts early without interrupting the workflow. Reduces costs and improves efficiency.

Visual Quality Checks: Advanced camera systems detect even hard-to-see surface flaws. Key to improving product quality.

AI and Image Processing: Analyze complex data and catch production errors automatically. Makes processes both fast and intelligent.

All these practices not only raise quality—they also help position your brand one step ahead in the market. When inspection processes are executed correctly, customer satisfaction becomes inevitable.

Frequently Asked Questions

What is end-of-line inspection in the automotive industry?

It is the final stage of testing and inspection during vehicle production, ensuring compliance with quality standards.

Why is this inspection so important?

It identifies production errors early, ensures safety and customer satisfaction, and protects brand image.

What kinds of tests are applied?

Both dynamic (performance) and static (assembly, structural integrity) tests are conducted. Both are essential to validate quality.

How do new technologies affect the process?

AI and automation speed up the process and reduce error rates. Quality and efficiency increase simultaneously.

How is efficiency measured?

Based on test duration, error rate per vehicle, automation level, and rework rate.

What has changed in quality standards?

New standards have become stricter. Emissions and safety now require more in-depth testing, which extends the process.

What does the future of this process look like?

With robotics, VR applications, and advanced imaging technologies, the process will become faster, more precise, and more digital.