20/06/2025

Improving Production Quality Through Assembly Completion Inspection

Production processes represent a challenging area where assembly quality and control stages must be meticulously managed. In this article, we examine in detail how control mechanisms in assembly processes can be optimized to increase production efficiency and quality. The topics covered include a general overview of assembly processes, the importance of assembly completion control, and the methods and techniques used in this control process. Additionally, we evaluate example applications demonstrating how these methods can be successfully integrated into production processes. This article, which aims to optimize assembly control processes in every detail, serves as an indispensable guide for industry professionals.

Overview of the Assembly Process: Basics and Importance

Assembly is the backbone of the production process. It’s not just about putting different parts together—it also determines the product’s quality and lifespan. Incomplete or faulty assembly directly results in performance loss.

As important as proper techniques and quality materials are, process supervision is equally critical. Inspections conducted from start to finish help identify potential issues early. That way, the production line doesn’t stop unnecessarily, and the product doesn’t go to waste.

Assembly completion checks ensure that each unit complies with standards. These checks must be supported by a solid quality assurance system to keep the production line operating at a high standard with minimal waste.

Right materials, effective techniques, strict supervision… when these three come together, costs go down and satisfaction goes up. It’s that simple. All that’s left is to continuously improve processes and upgrade control technologies.

What Is Assembly Completion Control and Why Is It Necessary?

This check verifies that the assembly process has been completed correctly. The goal is to eliminate errors from the very beginning. When applied properly, it boosts quality and reduces customer complaints.

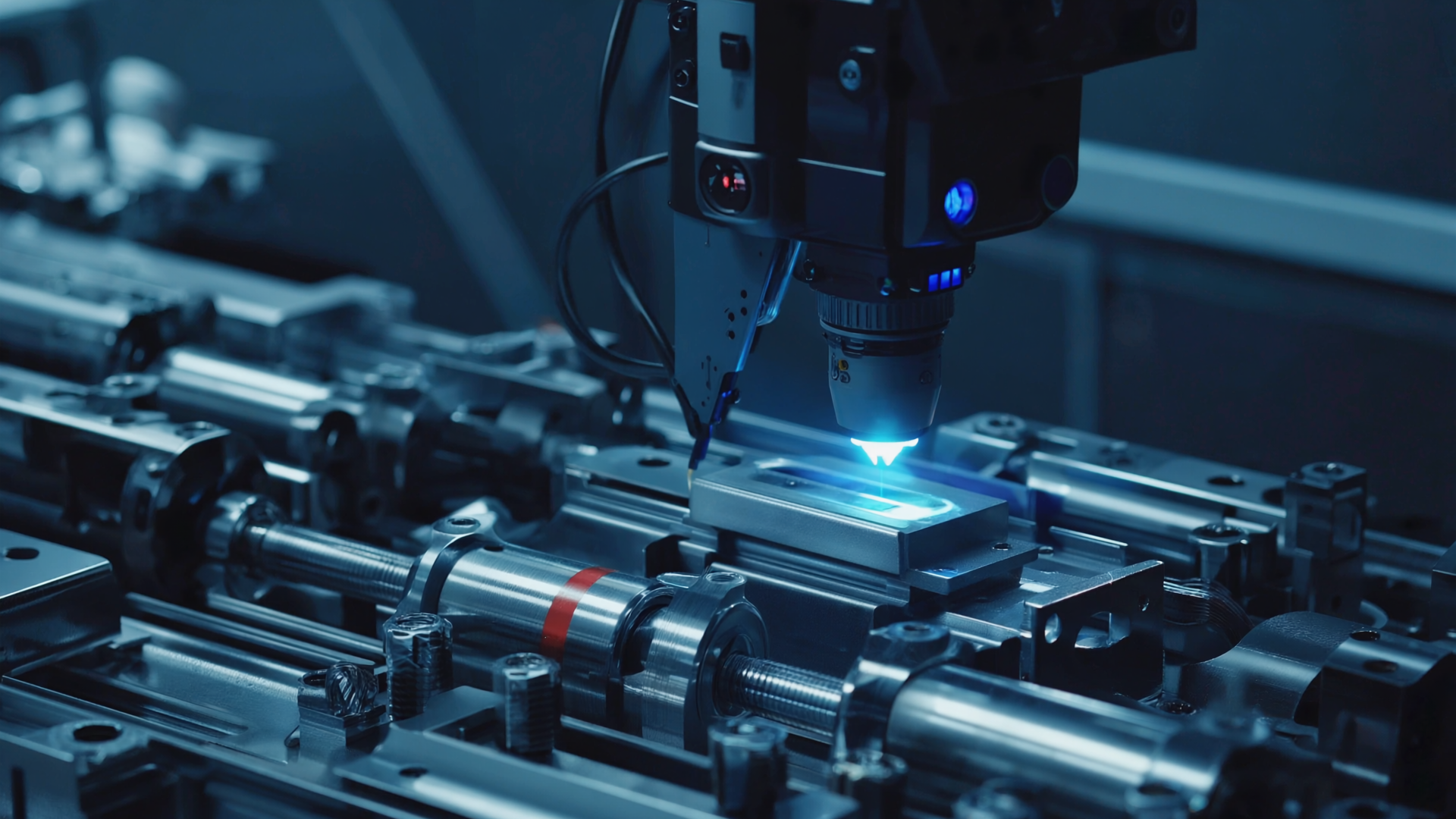

Traditional methods like visual and physical inspections are being replaced by AI and image processing systems. These systems are fast and precise—they detect errors instantly.

Such inspections make every step of the production line transparent. Continuous monitoring ensures continuity. If there’s a deviation from the standard, immediate action is taken.

Assembly errors not only affect quality but also lead to cost crises. That’s why starting with proper control means avoiding problems later.

Control Techniques and Steps to Improve Assembly Quality

The control process begins by verifying that each part is correctly positioned. The system may work automatically or be supervised by experienced personnel. The goal remains the same: error-free products.

This is where image processing systems come into play. Defective parts, burrs, warping—everything is detected within seconds. It allows for corrections without halting the production line.

AI-powered systems take it a step further. They learn on their own, predict issues, and respond proactively. This makes the assembly line more efficient and flexible.

For diverse parts and complex assemblies, the control system must be integrated with quality management. Only then can maximum efficiency be achieved and production meet market demands.

Production with Successful Assembly Control Applications

Assembly control is one of the most critical steps in manufacturing. If you want to produce quality products, your control system must be reliable. Otherwise, an assembly error can ruin the entire process.

Image processing and AI-based systems have taken control to a whole new level. Instant interventions, rapid analysis, and uninterrupted production are now possible.

When these systems are combined with a strong quality assurance infrastructure, both errors and costs decrease. Early intervention in the process prevents major losses down the line.

Assembly inspection isn’t just about product quality—it’s also a strategic move for customer satisfaction and competitive advantage. Improve, update, and never compromise.

Frequently Asked Questions

What is assembly completion control?

It’s the inspection process that checks whether each step of the assembly has been correctly performed. If there’s an error, it’s detected before the product is even packaged.

How does this inspection process improve production quality?

It detects errors early, giving the chance to correct them. This results in higher product quality and increased customer satisfaction.

What techniques are used in the assembly control process?

Visual inspections, automatic sensor systems, X-ray scanning, image processing software, and sometimes AI algorithms.

In which industries is this control especially important?

Industries like automotive, aerospace, electronics, and medical—where zero-error is essential.

Are these inspections beneficial in terms of cost and time?

They may seem like an extra step at first, but in the long run, they reduce costs and save time by preventing defective production.

What are the key factors for successful assembly control?

Clear checklists, trained personnel, regular reporting, and continuous improvement mechanisms are essential.

What are the common issues?

Human error, lack of proper documentation, and pressure for fast production. That’s why systematic inspection and technology are a must.